When you roll out of bed in the morning and fumble for the shower faucet, hot water soon emerges to pull you from slumber. Irrespective of your pre-coffee fog, we bet that almost none of those early morning minutes are spent thinking about how that water was made hot in the first place. The invisibility of water heaters in our daily lives means that, despite their vital role, most people rarely think about their water heaters, and think even less about the efficiency of these essential systems.

Today’s post will detail the design and capabilities of commercial heat pump water heaters (HPWHs). We’ll provide information about the legacy technologies and the plug-and-play solution for unitary (think residential) water heaters before discussing the path to decarbonizing water heating in commercial buildings.

Let’s review the two legacy technologies that make water hot.

Old-School Water Heating

Method one is a gas flame. Gas water heaters burn natural gas inside the shell of the water heater. The hot air from combustion then runs through a heat exchanger to transfer the heat to the water sitting in the tank. This method is effective but has drawbacks. For one, it’s not efficient. A typical residential tank available today is about 64% efficient. This means that if you burn 100 units of gas, 36 of those units are lost as uncaptured heat that goes out of the exhaust. Historically, the efficiency has been even lower with many older unit efficiencies hovering just above 50%. Beyond the inefficiency, reliance on direct combustion of fossil fuels does not provide a path to decarbonization and contributes local emissions like nitrogen oxide.

Method two for generating hot water is an electric coil inside your water heater—think of an electric stovetop or toaster submerged in water.[1] Those coils take electricity and convert the energy into heat which then directly warms the water in the tank. This water heater has the advantage of no direct emissions because there is no combustion, and the energy efficiency is typically around 90%. But the electric resistance water heater pales in comparison to the efficiency of the heat pump water heater.

The Path Forward in Decarbonized Water Heating

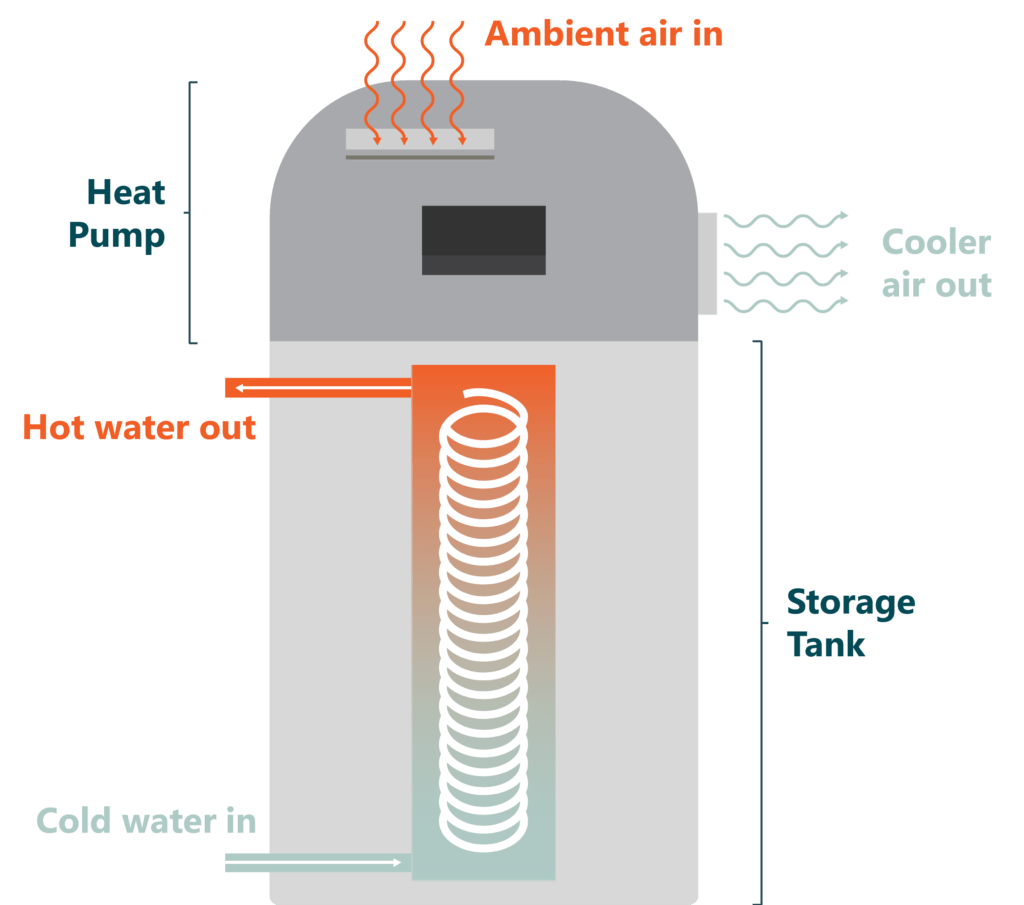

The star of decarbonized and efficient water heating is the HPWH, which is often over 300% efficient.[2] HPWHs use the refrigeration cycle to transfer heat from the ambient air to cold water. The most familiar HPWHs are unitary residential models—picture a tank in a basement or closet with a heat pump sitting on top. A simple diagram is provided below. Such units are becoming more widely accepted and available. The Northwest Energy Efficiency Alliance recently found that unitary HPWHs are approaching 8% of electric water heater sales in the Northwest.[3] That prevalence has increased from a negligible market share even a few years ago.

With this momentum behind unitary HPWHs, the path to decarbonizing water heating in smaller spaces is clear. But what do we do about commercial buildings?

Decarbonizing Commercial Water Heating

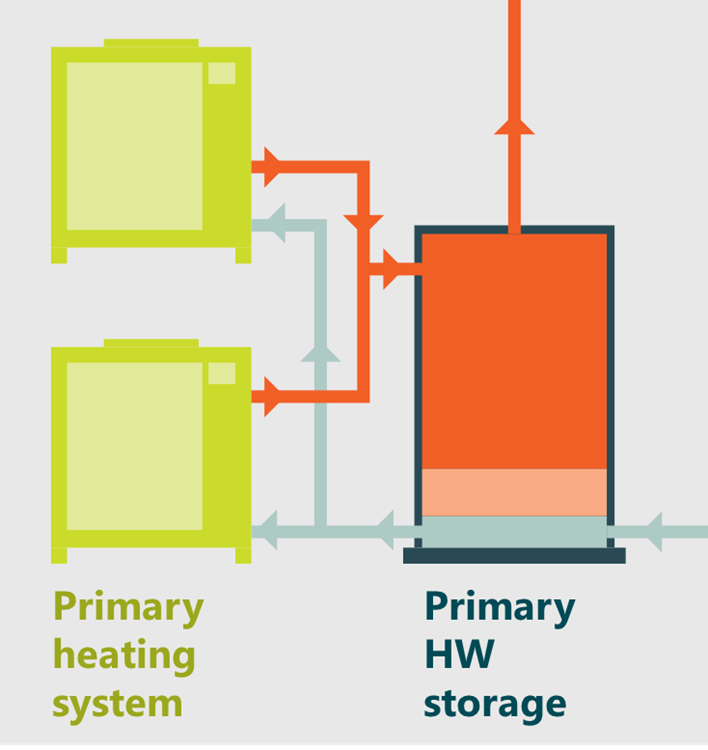

Commercial buildings often have large, central water heaters that generate water in one place and distribute it throughout the building. Many central water heaters rely on fossil fuel combustion to create hot water quickly and in large quantities. Fortunately, there is an emerging electric heat pump solution for the commercial space too. Below, we explore how commercial HPWHs work and why the technology is promising.

Unlike unitary HPWHs, which combine the hot water storage tank with the heat pump in a single unit, central HPWH systems separate hot water storage from the heat pump heating apparatus (see Image 2 below). This is similar to central fossil fuel boiler systems; however, there are critical differences in the design and operation of central HPWH systems and central domestic hot water boiler systems.

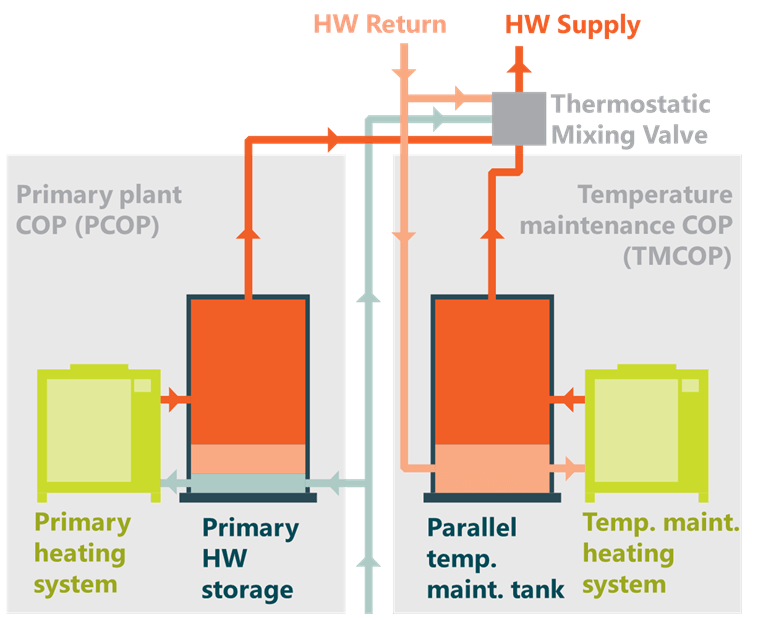

Unlike traditional central boilers, central HPWH systems must manage temperature maintenance separately from primary water heating as illustrated in Image 3. The primary water heating system includes both a HPWH and hot water storage tanks. Its purpose is to make incoming cold water into hot water. Many primary systems use single-pass HPWHs, which increase water temperatures by 60° Fahrenheit (F) or more in a single pass through the HPWH. The hot water exits the HPWH into the primary hot water storage tanks. Unlike traditional central boiler systems, which are often sized to meet peak demand loads, the primary HPWH is not. Instead, the HPWH capacity is sized with the primary hot water storage volume.

In this setup, there is enough hot water storage to meet peak demands. Furthermore, the HPWH has enough capacity to refill the storage between demand peaks.

Designing the Right Commercial Heat Pump Water Heater

To maximize the use of the efficient heat pump mechanism, commercial HPWH systems ideally operate for extended periods of time. Sometimes up to 16 hours per day! During that time, the HPWH is constantly producing hot water. Large storage volumes let a smaller HPWH produce sufficient hot water for peak loads and replenish it during nonpeak periods.[4]

As mentioned, central HPWH systems manage temperature maintenance differently than traditional central boiler systems. Temperature maintenance compensates for heat losses associated with the distribution system within the building. Central systems often have significant distribution lines that require constant hot water circulation to ensure water is hot (about 120°F) when occupants turn on fixtures. This water, circulating via distribution piping, acts like a giant radiator cooling the water. Depending on the design of the distribution losses and the hot water load profile[5] for the building, the temperature maintenance losses can be significant.

Central boiler systems address temperature maintenance by bringing cooled water directly back to the hot water storage tank or boiler for reheating. However, in central HPWH systems, this is not ideal. A single-pass heat pump water heater operates most efficiently when taking in cold water (around 50°F to 55°F) and heating water up to 125°F or higher. As discussed, the primary water heating system often uses a single-pass HPWH. If circulation water returns directly into the hot water storage tank, the cooler water mixes with the hot water and reduces temperature stratification. Without good temperature stratification, HPWH efficiency reduces and may trigger an alarm that stops the HPWH from functioning.

In central HPWH systems, having a separate temperature maintenance system, including a storage tank and heating system, is best. This secondary heating system and storage tank are responsible for managing temperature losses from circulating water through the distribution piping. There are multiple ways to manage the circulation of return water reheating—but that’s a topic for another day!

The Path to Mass Adoption of Commercial Heat Pump Water Heaters

Although central HPWHs are a new technology, they’re gaining traction. This is because of hard work by groups like the Bonneville Power Administration Emerging Technologies Advanced Water Heating Central Heat Pump Water Heater Work Group and the Advanced Water Heating Initiative. With these groups, the Northwest Energy Efficiency Alliance has added commercial HPWHs to their Advanced Water Heating Specification v8.0 and multiple manufacturers have products available on the market in skid-type packages. All these developments are beneficial as more regions are requiring HPWHs for central systems in building codes. Additionally, central HPWHs represent an ideal demand response technology, which we will discuss in a future blog post.

If you’d like more information on commercial HPWHs and their demand response capabilities, be sure to join our upcoming Association of Energy Services Professionals’ webinar on November 3 with Ecotope and SkyCentrics.

[1] Cadeo does not endorse DIY water heaters involving submerging a toaster into a bucket of water

[2] At this point, most people interject and ask, “but doesn’t this break the second law of thermodynamics?”. The answer is no, because HPWHs do not create heat; they move heat.

[3] MPER 5, NEEA.

[4] If you are interested in better understanding the tradeoff between HPWH capacity and hot water storage volume, check out Ecotope’s Ecosizer tool, which is free online central HPWH sizing tool for multifamily buildings.

[5] Load profile: nerdy term for when hot water is needed and how much.